Service Hotline

Service Hotline

MCI-2018

市 場 價(jià):¥0

優(yōu) 惠 價(jià):¥1

庫 存:0

PRODUCT DESCRIPTION:

MCI-2018 is a 100% silane concrete sealer containing time-proven Migrating Corrosion Inhibitors (MCI). MCI- 2018 penetrates deep into concrete providing corrosion protection to reinforcing steel from existing water and chloride ions, or other contaminants. MCI-2018 also provides water repellency by chemically reacting with the cementitious substrate under proper application, de- creasing the ingress of additional aggressive materials.

E-Mail:zzgvci@163.com

商品詳細(xì)

MCI-2018 UV contains a UV dye to confirm applications without affecting the appreance of the surface.

MCI-2018 and MCI 2018 VO are available with a per- menant Red or Blue stain.

PRIMARY APPLICATIONS

?Commercial buildings

?Parking garages

?Bridge decks or bridge structures

?Tunnels

?Jetties/Piers and other marine structures

?Off-shore oil platforms

?Any other reinforced concrete structure

ADVANTAGES

?Migrates into even the densest concrete

?Forms a monomolecular corrosion inhibiting layer on the steel, inhibiting the electrochemical corrosion process between metal and chloride, oxygen, and moisture in concrete

?Treated substrates are hydrophobic and retain their original appearance

?Surfaces remain fully breathable and maintain their natural moisture-vapor transmission

?Blocks carbonation and chloride ion intrusion

?Extends the service life of structures

?Easy application by spray, roller, or squeegee

?Non-toxic, contains no nitrites, phosphates, or chromates

?No blushing, peeling, or yellowing

?Complies with Alberta DOT Standards for Type 1b and Type 1c sealers

TYPICAL PROPERTIES

Appearance:

MCI-2018 Liquid (various colors) (and modifications)

pH 9-11(1% in water)

Density 7.3-7.7 lb/gal (0.87-0.92 kg/l)

VOC 2.2 lb/gal (245 g/l)

Coverage Rate 125-175 ft2/gal (3-4.3 m2/l)

COVERAGE RATE

Application rates will vary depending on surface porosity and number of applications. Approximate coverage rate is 125-175 ft2/gal. (3-4.3 m2/l). Before applying it is recommended that preliminary tests be carried out to determine dosing.

PACKAGING AND STORAGE

MCI-2018 should be kept away from moisture. When stored in original, airtight containers in a cool, well ven- tilated place, MCI-2018 has a shelf life of 12 months from the date of shipment. Stir thoroughly before use.

MCI-2018 is available in 5 gallon (19 liter) pails and 55 gallon (208 liter) drums.

TECHNICAL DATA FROM LABORATORY TESTS

Alberta Transportation Specification B388

MCI-2018 meets Alberta DOT Type 1b and Type 1c sealer requirements for vapor transmission and water- proofing performance.

NCHRP - Series II

Reduction in Chloride Ion Content

Single coat application, at 125 ft2/gal (3 m2/l), showed an 88% reduction in chloride ion content.

NCHRP - Series IV, Southern Exposure Accelerated Weathering Tests

Single coat application at 125 ft2/gal (3 m2/l), had zero discoloration and reduced chloride ion intrusion by 98% compared to a control.

ASTM C-642

Water Absorption of Concrete

Single coat application, at 125 ft2/gal (3 m2/l), showed a 74% reduction after 50 days compared to the control.

ASTM C-672

Standard Test Method for Scaling Resistance of Concrete Surfaces Exposed to Deicing Chemicals

Results show little or no change after more than 50 cycles of freeze-thaw with the use of deicing salts on coated concrete samples.

AASHTO T-259

Resistance of Concrete to Chloride Ion Penetration Treated samples showed an 82.6% reduction in chloride ion penetration compared to the control. Depths from 0.5-1.0 inches contained negligible amounts of chloride ions.

ASTM E-514

Water Penetration and Leakage Through Masonry Treated samples had a 95% reduction in leakage rate compared to the control.

Federal Specification SS-W-110C

Water Repellency

Single coat application at 125 ft2/gal (3 m2/l), resulted in a 0.39% water absorption; exceeding the 1.0% specification maximum.

*According to Cortec Corporation Laboratory test report 08-121-1425

**Protecsil is a registered trademark of Evonik Industries

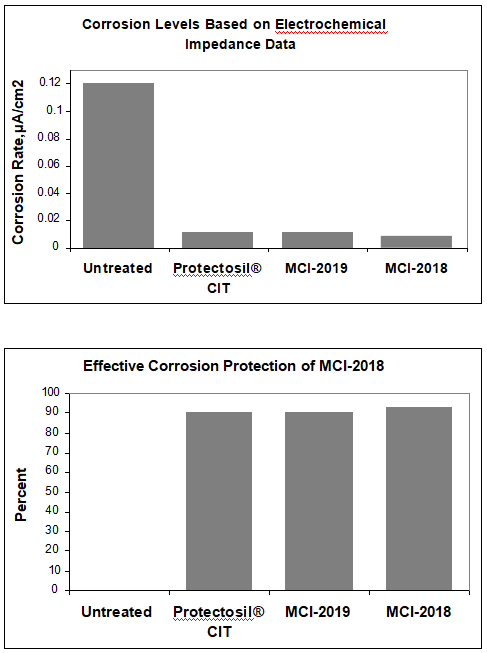

As the graph indicates, MCI-2018 provides >92% protection from corrosion when compared to untreated concrete and outperforms the competitive products.

APPLICATION

Surfaces should be free of standing water, surface dirt, dust, oils, grease, curing compounds, efflourescence, laitance, and other contaminants. MCI-2018 may be applied to damp surfaces, although dry surfaces are preferred to achieve maximum penetration into the substrate.

Application can be performed using airless sprayer, roller, or brush. When a brush or roller is used, repeated applications should be made until the surface remains moist for a few minutes. If an airless is used, applica- tion should continue until the substrate is thoroughly saturated. Sprayers should be fitted with solvent

hoses and gaskets.

For best results, two applications are recommended, with the second application being applied using a wet on wet technique, i.e.: the surface is wet from the first application, but not glossy. During application, precau- tions should be taken to protect the surrounding area from overspray and run-off.

CONSIDERATIONS

?Stir thoroughly before use

?Should be applied to sound, clean concrete that is free of oils, dirt, sealers, coatings, paints, membranes, or asphalt

?Should only be applied when temperatures are between 40-100°F (5-37°C)

?Should not be applied on extremely windy days when evaporation of the solvent would be too rapid

?Fresh concrete should be allowed to cure for 28 days before application

?Allow repair material to fully cure before applying MCI-2018

?If a coating will be used over MCI-2018, a seven day waiting period is recommended before application of that coating. A compatibility test should be performed prior to application

?Allow 24 hours for curing if a membrane will be applied over MCI-2018

?Should not be used on structures under hydrostatic pressure

CONSIDERATIONS

?Stir thoroughly before use

?Should be applied to sound, clean concrete that is free of oils, dirt, sealers, coatings, paints, membranes, or asphalt

?Should only be applied when temperatures are between 40-100°F (5-37°C)

?Should not be applied on extremely windy days when evaporation of the solvent would be too rapid

?Fresh concrete should be allowed to cure for 28 days before application

?Allow repair material to fully cure before applying MCI-2018

?If a coating will be used over MCI-2018, a seven day waiting period is recommended before application of that coating. A compatibility test should be performed prior to application

?Allow 24 hours for curing if a membrane will be applied over MCI-2018

?Should not be used on structures under hydrostatic pressure

Qingdao Cortec Rust Proof Materials Co., Ltd.,

Consultation hotline:0532-80989502

Sales Hotline:135-0535-2885

E-mail:zzgvci@163.com

QQ:592192408

Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone

Alibaba store:https://shop1420649126784.1688.com

Qingdao Cortec Rust Proof Materials Co., Ltd., the General Agent in China authorized by CORTEC Mobile phone:13505352885 Telephone:0532-80989502 Website:greattone.com.cn Mailbox:zzgvci@163.com Alibaba shop link click on the entrance Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone

Qingdao Cortec Rust Proof Materials Co., Ltd., the General Agent in China authorized by CORTEC Mobile phone:13505352885 Telephone:0532-80989502 Website:greattone.com.cn Mailbox:zzgvci@163.com Alibaba shop link click on the entrance Address:Room 2073, No. 12, chongmingdao East Road, Qingdao Economic Development Zone